Inductors are coiled electromagnetic devices that store energy in a magnetic field. Transformers and other specialized electrical equipment require custom inductors that meet their specific power requirements.

MPS Industries is a leading manufacturer of custom electronic components, specializing in inductors, transformers, chokes, and more. We design and build custom inductors that meet specific needs in the automotive, medical, aerospace, military, telecommunications, and other electronics industries.

Learn more about the different types of inductors available, as well as their applications and customization options.

What Is an Inductor?

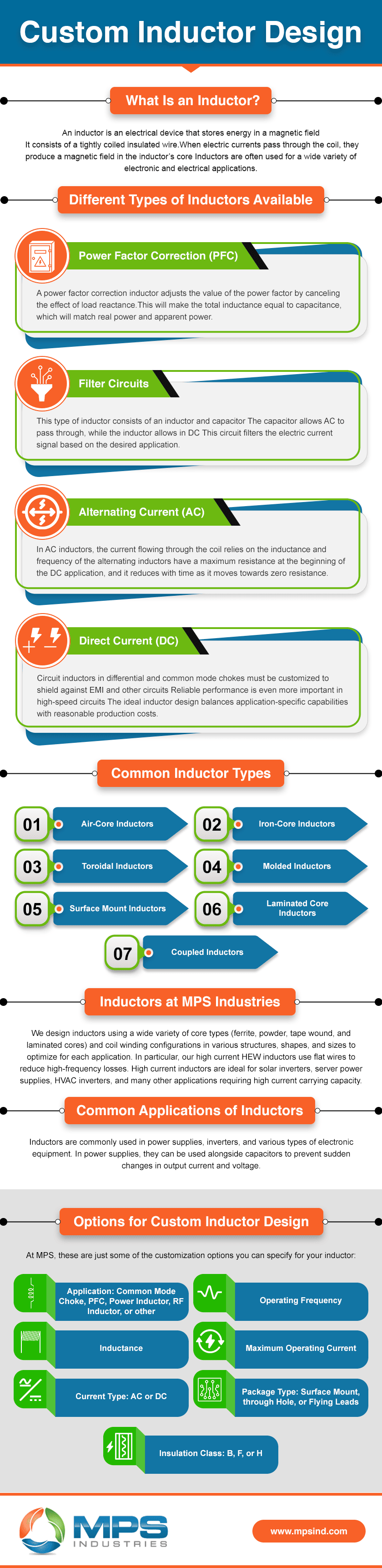

An inductor is an electrical device that stores energy in a magnetic field. It consists of a tightly coiled insulated wire. When electric currents pass through the coil, they produce a magnetic field in the inductor’s core. Inductors are often used for a wide variety of electronic and electrical applications.

Different Types of Inductors Available

There are different types of inductors that vary according to the application and the inductor circuit category. Here is a breakdown of the different kinds of available inductors.

Inductor Circuit Categories

Types of inductor circuits include:

- Power factor correction (PFC): A power factor correction inductor adjusts the value of the power factor by canceling the effect of load reactance. This will make the total inductance equal to capacitance, which will match real power and apparent power. Ideally, the power factor should be as close to 1 as possible. PFC inductors are best for low-power applications.

- Filter circuits: This type of inductor consists of an inductor and capacitor. The capacitor allows AC to pass through, while the inductor allows in DC. This circuit filters the electric current signal based on the desired application.

- Alternating current (AC): In AC inductors, the current flowing through the coil relies on the inductance and frequency of the alternating inductors have a maximum resistance at the beginning of the DC application, and it reduces with time as it moves towards zero resistance. ency of the alternating source.

- Direct current (DC): Circuit inductors in differential and common mode chokes must be customized to shield against EMI and other circuits. Reliable performance is even more important in high-speed circuits. The ideal inductor design balances application-specific capabilities with reasonable production costs.

Common Inductor Types

At MPS, the most common type of inductor is the toroidal inductor. We also specialize in helical edge wound (HEW) inductors using flat wire. Other kinds of inductors include:

- Air-core inductors

- Iron-core inductors

- Toroidal inductors

- Molded inductors

- Surface mount inductors

- Laminated core inductors

- Coupled inductors

Inductors at MPS Industries

At MPS, we create inductors specific to our clients’ requirements. We design inductors using a wide variety of core types (ferrite, powder, tape wound, and laminated cores) and coil winding configurations in various structures, shapes, and sizes to optimize for each application. In particular, our high current HEW inductors use flat wires to reduce high-frequency losses. High current inductors are ideal for solar inverters, server power supplies, HVAC inverters, and many other applications requiring high current carrying capacity.

Common Applications of Inductors

Inductors are commonly used in power supplies, inverters, and various types of electronic equipment. In power supplies, they can be used alongside capacitors to prevent sudden changes in output current and voltage. Regardless of application, MPS Industries takes great care to design the best inductor—with the lowest possible production and material costs—for the intended application.

Options for Custom Inductor Design

Every operation that requires inductors can benefit from custom design. The investment in custom inductors is worthwhile because they are optimized for their exact application.

At MPS, these are just some of the customization options you can specify for your inductor:

- Application: common mode choke, PFC, power inductor, RF inductor, or other

- Operating frequency

- Inductance

- Maximum operating current

- Current type: AC or DC

- Package type: surface mount, through hole, or flying leads

- Insulation class: B, F, or H

How to Request Custom Inductors

To request a custom inductor from us, browse our existing catalog and ask for modifications or request a new custom design for your project.

Contact MPS Industries for Custom Inductor Design

A custom inductor is crucial in electronic and electrical applications, especially those that require high currents. MPS Industries is a leading custom inductor manufacturer that can help you come up with an ideal solution for your unique project. Contact us or request information to learn more about our custom inductor design capabilities.