What Is Active Power Factor Correction (PFC)?

Electrical devices and circuits aren’t 100% efficient—some electrical power input will always be lost, leading to lower output power. This ratio of “apparent” power (or input) to “real” power (output) is the power factor (PF). The closer the power factor of a device or circuit is to 1:1, the more efficiently it performs. This criterion…

New HWI28P1-045-111B Filter Inductor

Introducing the New HWI28P1-045-111B Filter Inductor: A Game-Changer in High-Current Applications MPS Industries stands at the forefront of technological innovation in magnetic components, continually pushing the boundaries of performance and efficiency. Introducing the new HWI28P1-045-111B Filter Inductor, which marks another milestone in our journey. This high-performance filter inductor, designed for demanding high-current applications, combines advanced…

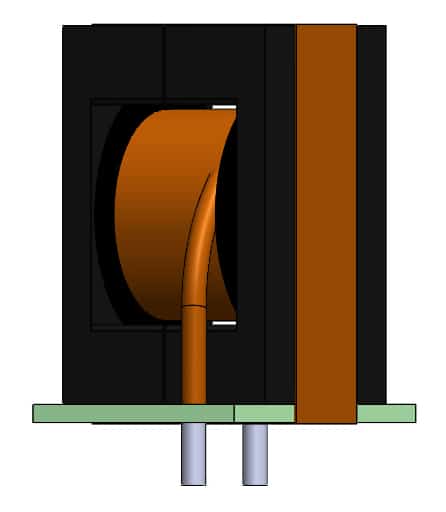

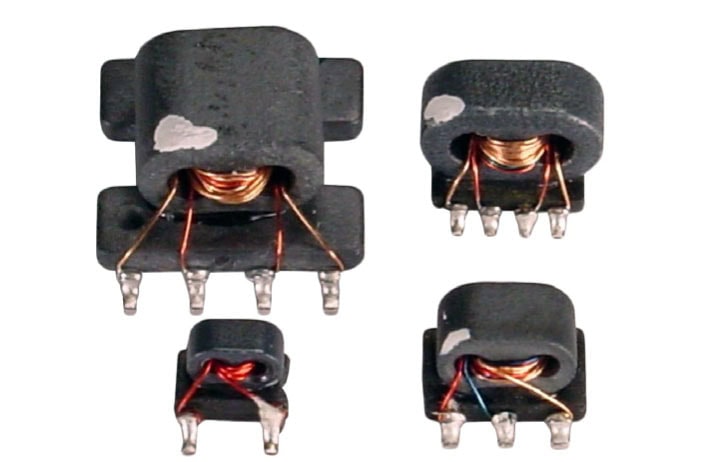

Coupled Inductors

The concept of coupled inductors, or transformer coils, is fundamental in the field of electrical engineering. Coupled inductors are used to transfer energy from a primary circuit to a secondary circuit, allowing for efficient and reliable power transmutation while providing some unique advantages not seen with other power conversion methods. What is a Coupled Inductor…

Harnessing the Power of Resonant Inductors for Efficient Energy Conversion

As energy efficiency becomes more important in modern electronics, resonant power conversion is becoming a prominent technique for minimizing energy loss in power electronics applications. The resonant inductor is an important component in resonant power conversion systems. The importance of resonant inductors in these systems and their application in zero voltage switching (ZVS) technology, which…

The Advantages and Disadvantages of LLC Transformers

LLC is one of many switch mode topologies for power supply and battery charging. The LLC transformer is critical in determining an LLC resonant converter’s efficiency. Resonant tanks are circuits comprised of inductors (L) and capacitors (C) that oscillate at a fixed frequency known as the resonant frequency. LLC transformers have two inductors and one…

Choke vs. Inductor: What’s the Difference?

Click to Expand Choke vs. Inductor: What’s the Difference? At MPS Industries, we specialize in manufacturing high-quality magnetic parts for automotive, medical, power distribution, and more. We’re ISO 9001:2015 certified, and we prioritize quality engineering practices to create products our clients can trust in critical applications, including inductors and chokes. Both chokes and inductors can…

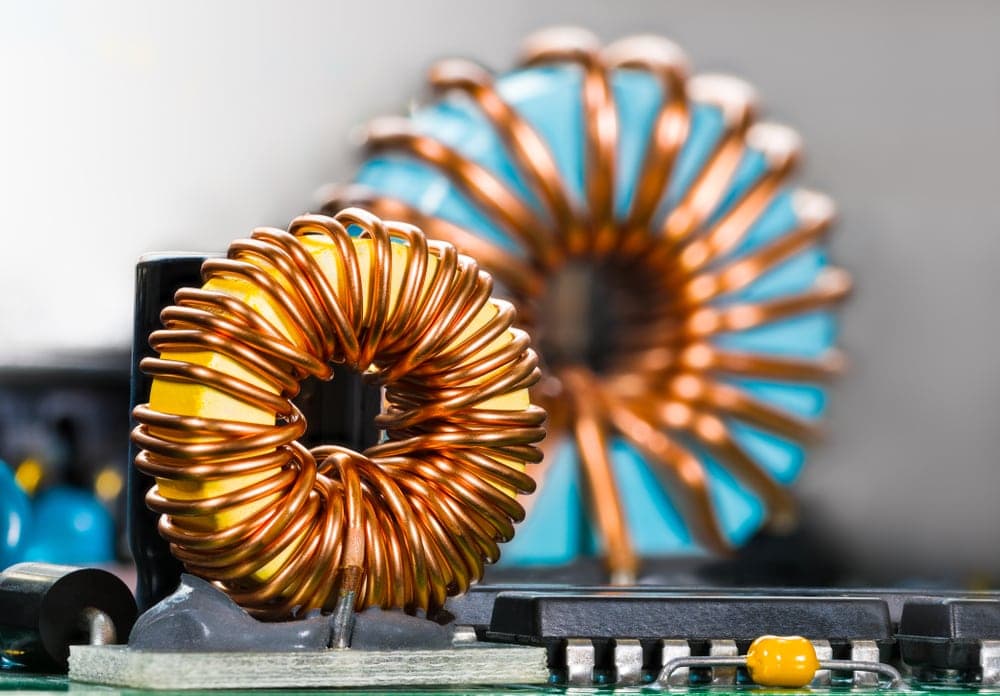

How Do Common Mode Chokes Work?

A common mode choke is an electromagnetic component that blocks high frequencies by passing direct currents (DC) and alternating currents (AC) through an electrical circuit. The choke gets its name because it blocks or “chokes” high-frequency signals while low-frequency signals pass through. This blog will cover the various aspects of common mode chokes and address…

Step-Up vs. Step-Down Transformers & How They Work

A transformer is an electrical component composed of two or more wire coils that transmit and convert electrical energy through electromagnetic induction. Transformers can increase or decrease electrical voltage by transferring energy from an input coil (known as the primary winding) to one or more outputs (secondary windings). These windings consist of a magnetic core…

What Is the Difference Between a Balun and RF Transformer?

Baluns and RF transformers are two distinct types of transformers – while they share similarities, they have many key differences in terms of operational functions and characteristics. In this blog, we’ll overview these two transformer types and their distinctions. Balun Transformers Balun transformers are used to convert an unbalanced signal to a balanced signal and…

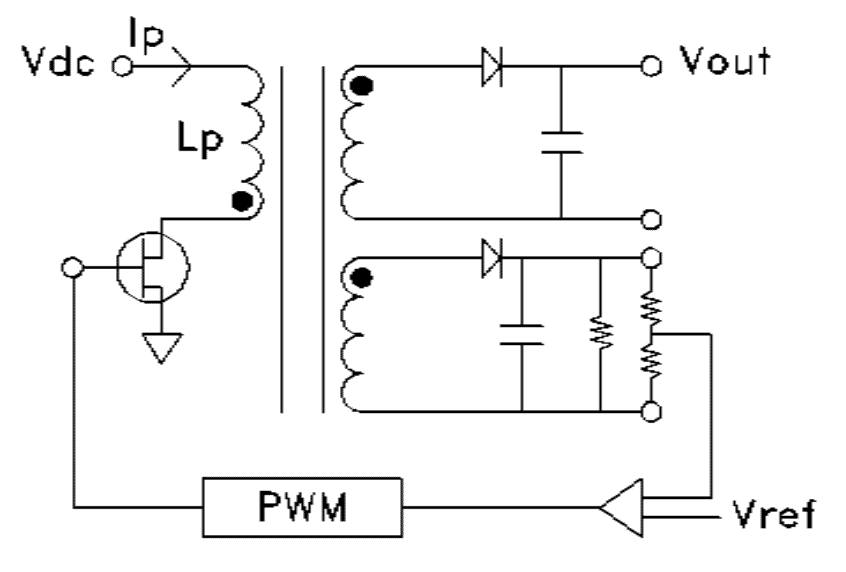

The Complete Guide to Flyback Transformers

When a power converter doesn’t require very high power – i.e. 200 watts or less – flyback converters are good choices due to their lower cost, decreased quantity of components, and simple design. Flyback converters are used in a variety of equipment, including televisions, LED lighting arrays, telecommunications, and industrial systems. One of the main…