2016 was a pivotal year for magnetic components. The presence of hydroelectricity, wind electricity and solar power was felt in a significant way as countries around the world pushed for clean and renewable sources of energy. In conjunction with this trend, electric cars also contributed to the green drive making waves across the planet. At…

2016 in Review: A Pivotal Year at MPS

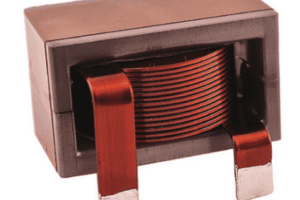

Before we give you a sneak-peek at MPS Industries’ 2017 agenda, let’s take an overview of 2016. It was a pivotal year for the engineers as they focused on bringing the best magnetic component innovations to a variety of industries, not limited to automotive, energy storage, solar, utility, wind, and HVAC. Our high-power, high-efficiency compact…

MPS Will Be Attending APEC 2016 to Showcase Our Quality Engineered Magnetic Components

APEC 2016, the premier global event in applied power electronics, focuses on both the applied and the practical aspects of the power electronic business. The 2016 APEC Conference and Expo will be taking place on March 20-24 at the Long Beach Convention & Entertainment Center in Long Beach, CA. We are looking forward to attending…

The Force Between our Magnetic Components and the Auto and Energy Industries

We take great pride in the production of our magnetic components, and we continue to improve their quality and capabilities as technology continues to change the manufacturing world. It’s always interesting for us to see how our magnetic components fit into specific applications, which can range from a variety of different industries. Recently, we have…