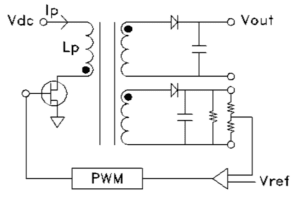

When a power converter doesn’t require very high power – i.e. 200 watts or less – flyback converters are good choices due to their lower cost, decreased quantity of components, and simple design. Flyback converters are used in a variety of equipment, including televisions, LED lighting arrays, telecommunications, and industrial systems. One of the main…

Switch Mode Power Supply Transformers FAQ

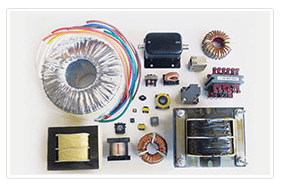

MPS Industries is a U.S.-based magnetic components manufacturer specializing in the design of custom transformers, inductors, common mode chokes, current sensors and many other custom magnetics. Switch mode power supply (SMPS) transformers use different switching topologies, transferring the required power from input to output in the electronic systems. Here, we have answered some of the…

What is a Toroidal Power Transformer?

Transformers are electrical devices that rely on electromagnetic induction to transfer energy from one circuit to another. Among the most common types of transformers are power transformers, which are generally used in electrical systems to step up (i.e., increase) or step down (i.e., decrease) voltage levels between circuits. These transformers are available in several variations,…

Magnetic Components 101: Transformers, Inductors, and Chokes

Magnetic components are passive elements that rely on an internal magnetic field to alter electrical current. They play a critical role in many electronic devices, equipment, and systems. Some of the industries that often make use of them include: Appliances: Magnetic components play critical roles in both common household and advanced industrial appliances (ranging from…

APEC 2018 is Just Around the Corner

This year from March 4-8, San Antonio, Texas is going to be a popular destination for more than just the San Antonio Spurs or the Alamo. These dates are set aside for the premier global event for everything related to power electronics, APEC 2018. Held at the Henry B. Gonzalez Convention Center, this 44,995 sq….

Manufacturing & Magnetics – An Important Industry Outlook

With 2017 officially closed, now is the time to look towards industry predictions in the new year. Industry Outlook Predictions Projections for 2018 show positive outlooks for three of the main industries MPS serves. The renewable energy sector, both globally and within the U.S., will always be at the forefront of debate and conversation. Renewables (in…

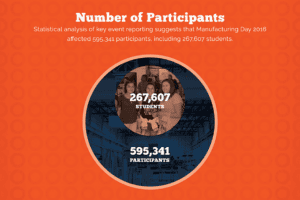

Help the Manufacturing Industry Celebrate National Manufacturing Day!

As the first Friday in October, National Manufacturing Day 2017 will happen on October 6th. As a prominent electronics component manufacturer, MPS Industries is happy to spread the word about NMD. This year the event promises to be a day full of education and encouragement for all attendees. What MFG DAY Means for the Industry…

The Automotive Recovery, Powered by MPS

Recent news and trends all point to a giant recovery for the American auto industry. Most major automakers saw moderate to large sales increases in 2012; one market research firm, Polk, now expects new car sales to increase by 6.6% in 2013, thanks to a recovering economy and growth in the pickup truck and midsize…

Electronics and the eCommerce Revolution

With Black Friday and Cyber Monday in the rear-view mirror, the holiday shopping season has hit full stride. As expected, these two highly anticipated shopping days did not disappoint in 2012; in fact, Cyber Monday was most likely the busiest eCommerce day in history up 30% from last year. In addition, both days proved that…