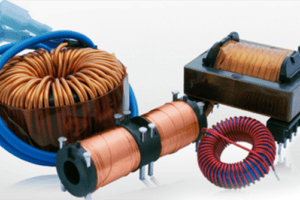

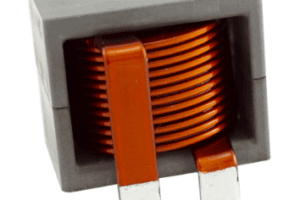

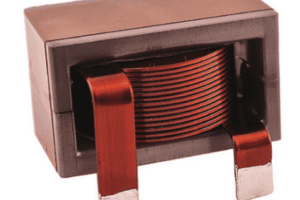

It’s one thing to be a generic electronic component manufacturer, churning out the same identical transformers, inductors, and magnetic components on a day-to-day basis. There’s certainly a market for that – plenty of applications use off-the-shelf parts. But for custom components, you need a manufacturer who can combine a task-oriented sales force and a smart,…

MPS Contributes to Clean Year Round

With Earth Day quickly approaching, our MPS Industries team is taking the time to assess how our magnetic components contribute to the global movement for clean, renewable energy sources. The annual day for celebrating green initiatives lands on April 22. Our Year’s Vision MPS Industries recently shared our expansion plan for 2017: extending our product…

MPS is Attending APEC 2017

This year we are attending APEC 2017 from March 26th through the 30th. Taking place at the Tampa Convention Center in Tampa, Florida, the conference is considered to be the “premiere global event in applied power electronics.” Attendees will learn about practical and applied sides of the power electronics business. What to expect at the…

2017 Expansion Plans to Benefit Our Customers

2016 was a pivotal year for magnetic components. The presence of hydroelectricity, wind electricity and solar power was felt in a significant way as countries around the world pushed for clean and renewable sources of energy. In conjunction with this trend, electric cars also contributed to the green drive making waves across the planet. At…

2016 in Review: A Pivotal Year at MPS

Before we give you a sneak-peek at MPS Industries’ 2017 agenda, let’s take an overview of 2016. It was a pivotal year for the engineers as they focused on bringing the best magnetic component innovations to a variety of industries, not limited to automotive, energy storage, solar, utility, wind, and HVAC. Our high-power, high-efficiency compact…

MPS Will Be Attending APEC 2016 to Showcase Our Quality Engineered Magnetic Components

APEC 2016, the premier global event in applied power electronics, focuses on both the applied and the practical aspects of the power electronic business. The 2016 APEC Conference and Expo will be taking place on March 20-24 at the Long Beach Convention & Entertainment Center in Long Beach, CA. We are looking forward to attending…

Off-Road Segment Gets A Hybrid Upgrade

Popularity among hybrid and electric vehicles have grown exponentially within the U.S. Tesla has stated they spend $0 on marketing yet demands have continued to grow. In fact, think about how you’ve never seen any ads or commercials from Tesla. With no marketing power how can it have such strong potential to take over the…

Save the Date: The AES Expo is Around the Corner!

In manufacturing, one of the most valuable, important things you can do is get out there and interact with your clients and industry leaders. And one of the best ways to do this is by attending trade shows. When you spend time at a trade show, you have the invaluable opportunity to interact with current…