03/2018 Optimize Your SMPS with MPS We Know High-Power Conversion Efficiency High-power conversion efficiency is important in your SMPS design, especially in your DC-DC switching converters. MPS Industries, Inc. is a supplier of magnetics for SMPS. We will work with you to select and design the most optimized components for your needs. This includes various…

12/2017 Custom Inductor Solutions

12/2017 Custom Inductor Solutions MPS’ HEW High Current Inductors are the most comprehensive on the market today! Options range from our standard smaller surface mount 30A inductors (HWIA2918S series) to larger customized chassis-mounted inductors, capable of handling up to 1000A. Our HEW inductors have less skin effect at high current for high frequency applications, as…

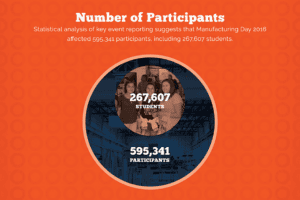

Help the Manufacturing Industry Celebrate National Manufacturing Day!

As the first Friday in October, National Manufacturing Day 2017 will happen on October 6th. As a prominent electronics component manufacturer, MPS Industries is happy to spread the word about NMD. This year the event promises to be a day full of education and encouragement for all attendees. What MFG DAY Means for the Industry…

MPS Shows Sales Increase as 2016-2017 Fiscal Year Comes to an End

As we reach the end of the fiscal year, our MPS Industries team has exciting news of our sales increase over last year. Our success in magnetic components manufacturing is attributable to both customers and employees alike. A big “thank you” to all of those who have supported and contributed to MPS this past year….

How to Meet the Needs and Stay Ahead of the Renewable Energy Industry

Renewable energy: it’s more than just a buzz word—it’s the hot topic in almost every major industry, and it’s here to stay. According to this article, in 2015 the country’s use of renewable energy hit its highest level since the 1930s when people relied almost solely on wood to heat their homes. From wind and…

Save the Date: The AES Expo is Around the Corner!

In manufacturing, one of the most valuable, important things you can do is get out there and interact with your clients and industry leaders. And one of the best ways to do this is by attending trade shows. When you spend time at a trade show, you have the invaluable opportunity to interact with current…

MPS Industries Expands And Promotes U.S Manufacturing

MPS Industries plans to expand new operations in Dallas, Texas. This office will be MPS Industries second office location in the U.S. The new office will cover producing and storing our latest high power products, and gaining more distribution authority. The new offices central location is advantageous for easy distribution to the rest of the U.S….

Advancing Energy Efficiency

A growing concern among many different industries is energy efficiency. From energy efficient cars, to an electricity grid that comes from renewable sources (or both if you’re Elon Musk), to the next phase in the Energy Efficiency and Security Act, the goal of more efficient ways to produce, store, and use energy are on the…

Augmented Reality and the Future of Electronics Technology

As we’ve mentioned in previous blogs, our industry is one that is constantly being inundated with new and exciting technologies, all of which are of interest to electronics manufacturers as interesting combinations of developments that seek to improve our lives. One exciting new technology we’re interested in here at MPS is the field of augmented…

MPS and Oceanic Research

Part of the exciting nature of our job here at MPS is the opportunity to be a part of fascinating projects from time to time. We think one of our latest projects is especially interesting, and worth talking about with you here on our blog. The Canadian Scientific Submersible Facility is a non-profit in Canada…